Our Sustainability Story

At Charles Samelson Inc., our legacy is built not just on beautiful, high-performance fabrics but on responsibility, durability, and care for the environments that benefit when high standards meet thoughtful practice.

Founded with deep roots in the textile and contract-fabric industry, we understand that what we produce and how we produce it ripple outward touching not only design and comfort, but worker welfare, material footprints, and the health of communities.

Here are the ways that we live up to that responsibility:

Ethical and Responsible

Supply Chain

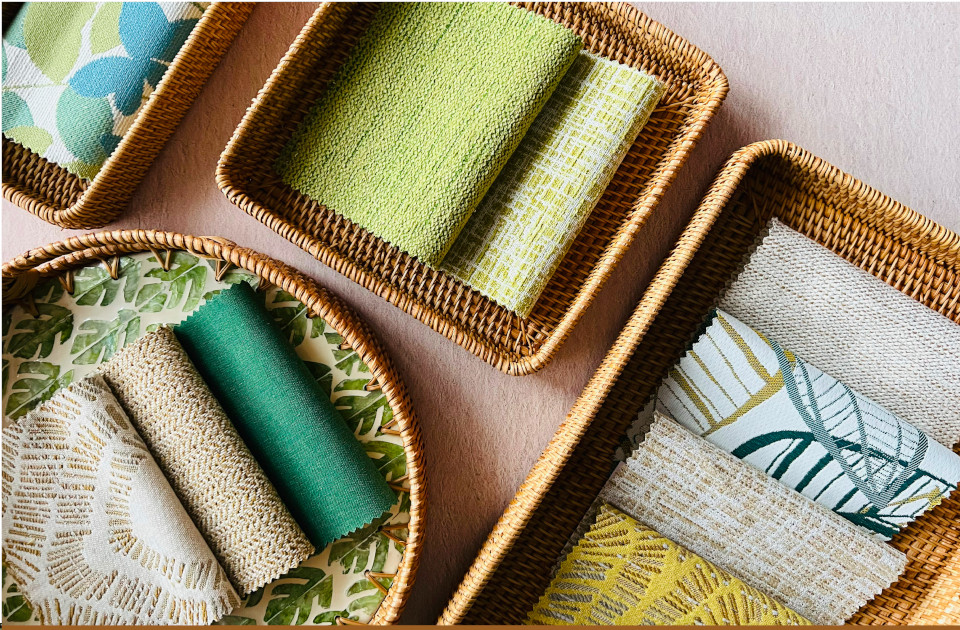

Every fabric we supply through our divisions Samelson-Chatelane, Coral and Aperture Contract are sourced through partners who share our commitment to compliance, transparency, and worker safety. We aim to work with mills and suppliers who abide by labor laws, respect human rights, and maintain safe, fair working conditions.

High Standards in Material Safety & Product Durability

We cater to the demanding environments of hospitality, cruise ship, healthcare, education, timeshare and institutional settings where durability, performance, and safety aren't optional, they are essential.

All of our fabrics are fire retardant, inherently complying with contract safety requirements for their specified end use.

We offer materials that are bleach-cleanable or barrier-coated, meaning they resist staining and microbial concerns - all of which extend product lifespan and reduce the need for replacements.

Minimizing Waste & Encouraging Longevity

Durability is sustainability. By producing fabrics and finishes that stand up to frequent use, harsh cleaning, and rigorous standards, we reduce turnover which means less waste. Rather than fast replacement, we prioritize fabrics and designs that last.

Thoughtful Choices of Material & Compliance

We are careful about what goes into our fabrics:

Using materials that are phthalate-free and safe for sensitive environments when possible. We also stock products that comply with various state and local regulations.

We ensure that our finishes, coatings and backing materials meet regulatory and environmental safety benchmarks.

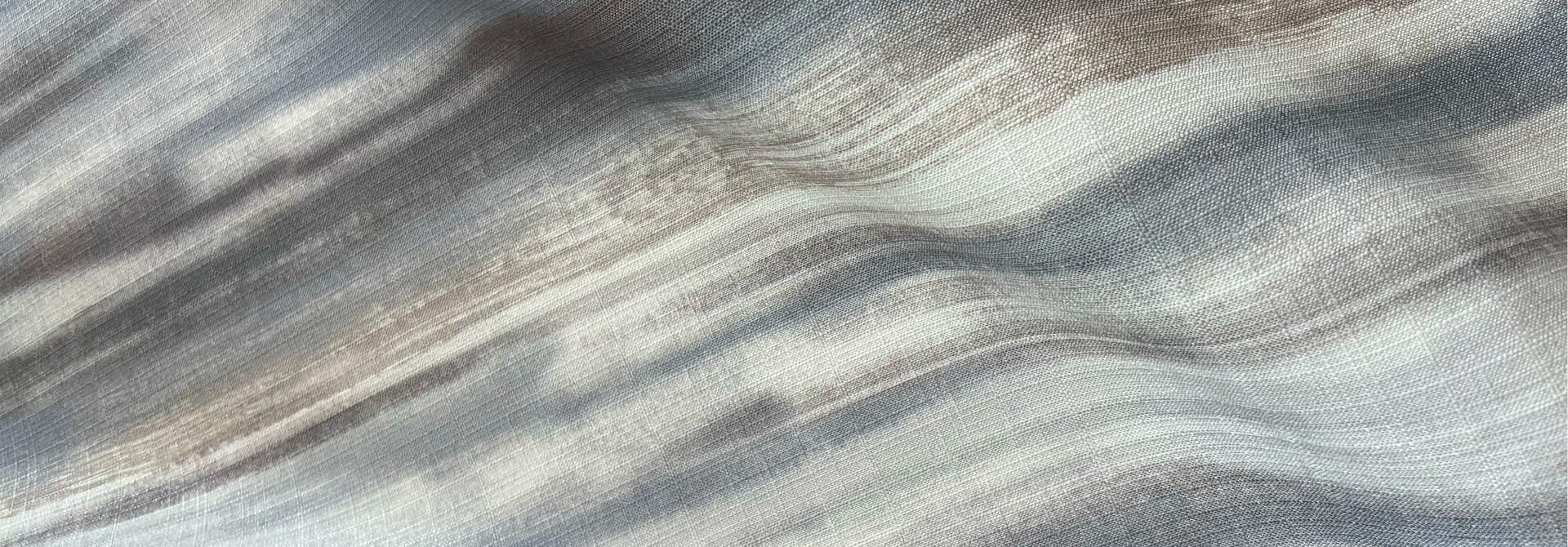

We offer both indoor and outdoor upholstery, decorative sheers, blackout fabrics, prints and wide-width FR products. This allows our clients to choose the right material for the right application. optimizing both performance and environmental impact.

Collaboration, Innovation, and Continuous Development

Being sustainable is not static, it means keeping pace with innovations in textile chemistry, finishing, and production processes.

We collaborate with design teams and customer partners to tailor solutions that balance aesthetic, cost, and environmental impact.

We invest in or favor manufacturing and finishing practices that reduce waste, improve efficiency, and ensure that every yard of fabric delivered meets both beauty and performance expectation.

Why It Matters

Because every time we choose a safer material, durable finish, or better partner, that choice adds up:

• Fewer fabrics discarded or replaced means less waste in landfills.

• Safer materials reduce environmental health risks.

• Longer-lasting products save resources - energy, water, and materials - across supply chains and over time.

• Responsible sourcing supports workers, communities, and ecosystems that often bear the cost of production.

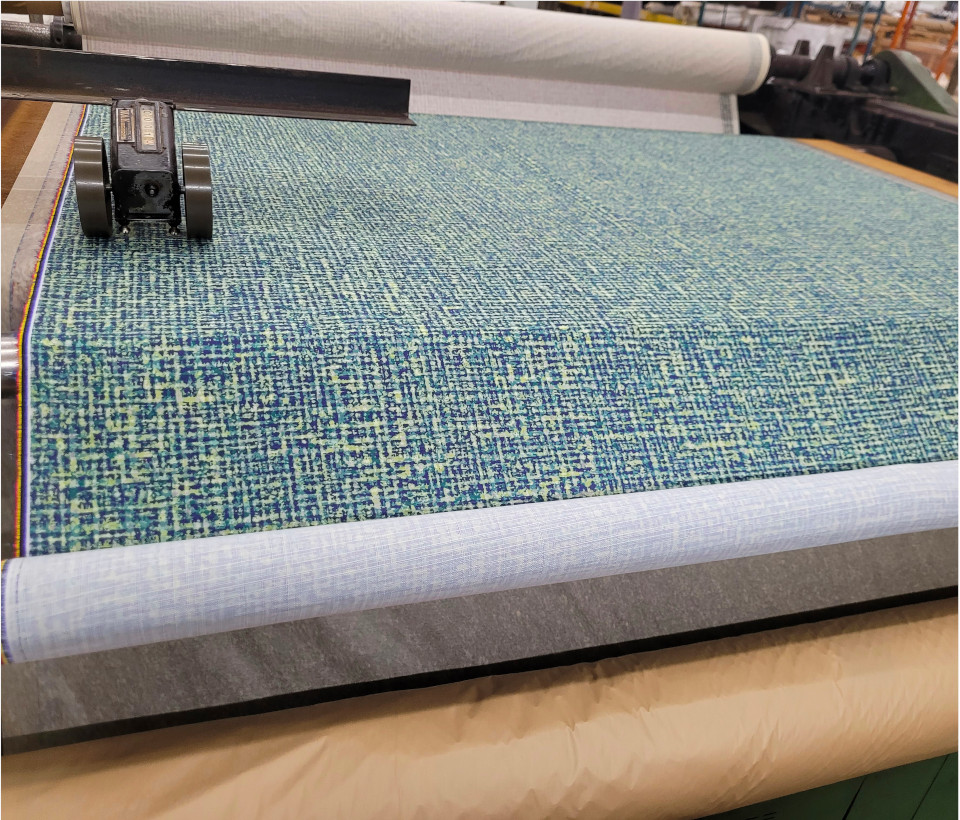

Local Source

We're committed to supporting local industry while reducing our environmental impact. By sourcing as much as possible from within the United States, we help strengthen domestic businesses and minimize the emissions associated with long-distance transportation. Working with local mills, printers, and suppliers allows us to maintain close relationships, ensure quality, and reduce our carbon footprint. This thoughtful approach keeps more of our production close to home - an important part of our mission to create beautiful, responsibly made textiles that reflect our commitment to sustainability.

Transfer Printing

Transfer printing helps us create beautiful textiles with a lighter environmental footprint. By using precise digital technology, we print only what's needed - dramatically reducing water use, energy consumption, and chemical waste. The process produces vibrant, long-lasting color without the need for large dye baths or excess materials, and even the transfer paper can often be recycled. This efficient, low-impact approach lets us deliver high-quality designs while staying true to our commitment to sustainability and responsible manufacturing.

At Charles Samelson, Inc., we believe that elegance, performance and integrity can coexist. Our promise is not only to provide fabrics that enhance spaces but to do so in a way that honors people, protects our planet, and upholds the standards of quality and care our customers expect.